|

Geolinks for

Underground Gas Storage

|

As of today, more than 1,000 Underground Gas Storage sites (UGS) are in operation in the world. The on-going fuel switch to decarbonize mobility and industry requires a significant number of new underground storage to store the newly produced Green Hydrogen.

Allowing safe and cost-effective Hydrogen storage, is a must to achieve the objectives related to limiting global warming.

|

Main Issue

that we solve

|

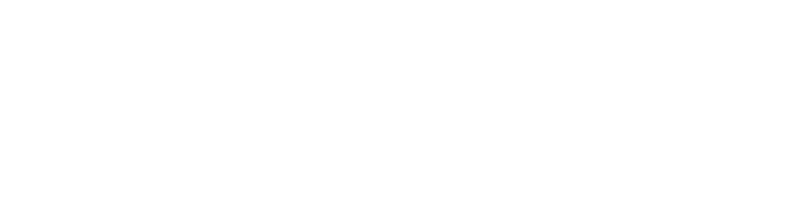

The diffuse gas leak is the main cause of accidents in UGS facilities (source Ineris, 2014), and there is no solution available today to detect leakage paths before the gas arrives at the surface, either through ageing subsurface infrastructures or faults in the underground,.

Gas storage sites in porous rocks are already heavily monitored on surface with various technologies such as piezometers, inclinometers, various gas detection systems, satellite imagery for ground deformation.

As part of the Well Integrated Monitoring system (WIMS), the wells are also heavily controlled and monitored.

The risk of induced seismicity is also monitored with the Microseismic technique.

However, as of today, no technology exists to monitor the underground part of the UGS site. Hence the underground represents the very major part of the geological storage area.

|

What is Geolinks

FlowTerra™ solution?

|

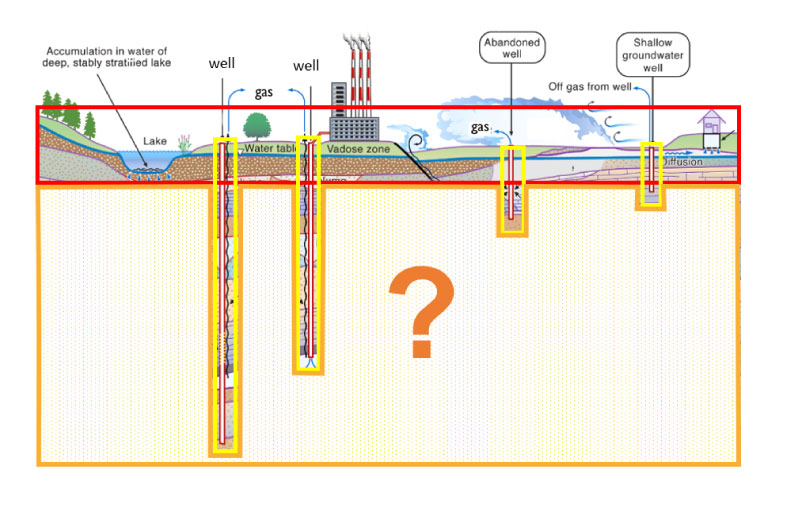

BREAKTHROUGH TECHNOLOGY: Since our solution does not require seismic sources and does not require dense seismic arrays, it addresses in a very cost-effective way to the current lack of underground monitoring solution.

Highly sensitive to rock saturation changes, our solution allow us to DIAGNOSE any suspicion of diffuse gas leak at depth, MONITOR operations between injection/production wells, and PREDICT water/gas contact..

|

Why choose

FlowTerra™ for UGS?

|

ENVIRONMENTALLY FRIENDLY

- Allows for safe and cost-effective gas storage

- No need for dense seismic arrays or seismic sources,

- No disturbance on local communities’ activities

EARLY DETECTION OF DIFFUSE GAS LEAKS

Due to a higher sensitivity to fluid movement, it enables early detection of leakage paths

CAN BE COMBINED WITH MICROSEISMIC DETECTION

COST EFFECTIVE MONITORING

FlowTerra monitoring stations are disposed on the ground, around the UGS facility.

Monitoring can be performed with less than 1 sensor per Km2 .

|

Use Case

|

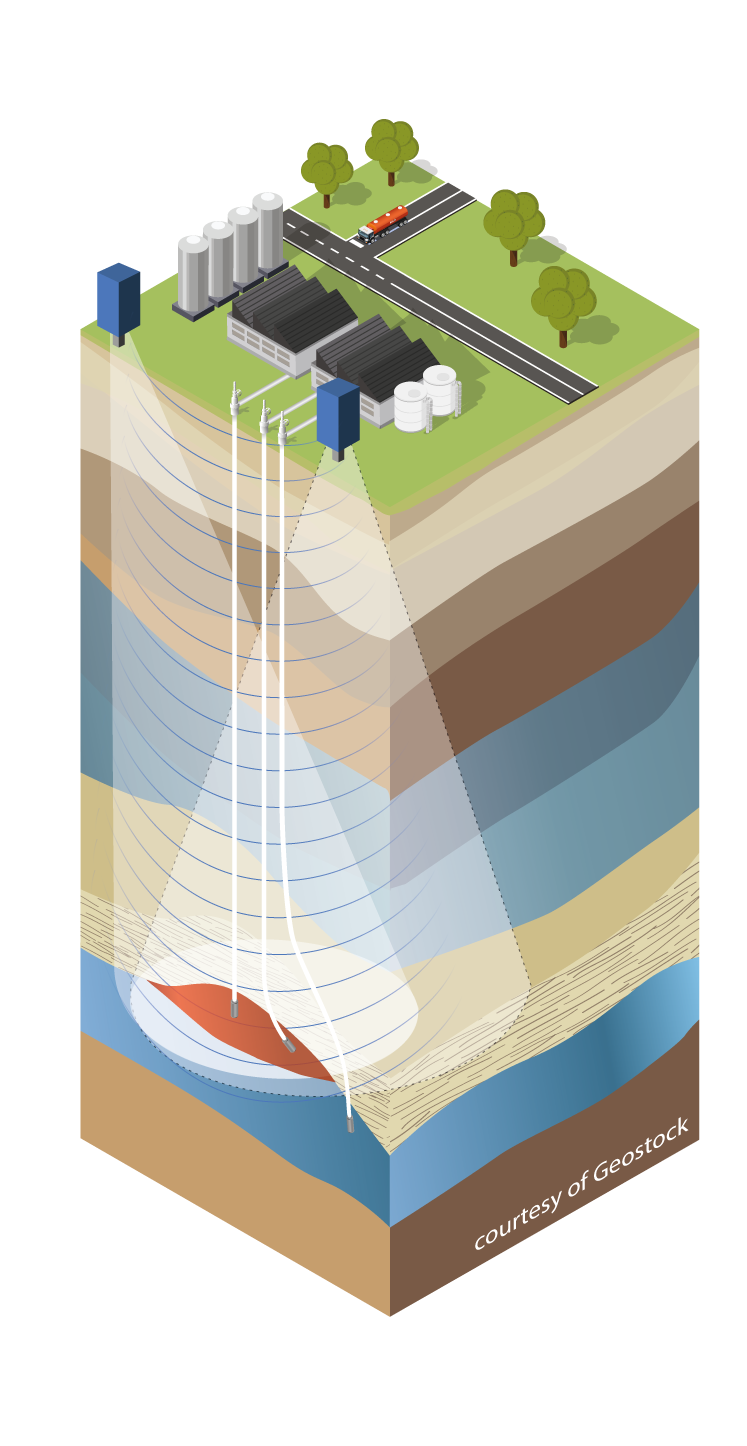

GeoLinks conducted its first large scale field test in 2021 over one underground gas storage facility located in the south of France.

It demonstrated that:

- The technique developed at the crustal scale was applicable at the UGS scale

- Mapping of saturation/pressure was possible

|

Did you know ?

|

The Rayleigh waves are more sensitive to saturation change than commonly used reflected waves. Moreover, they don’t require dense seismic arrays since they can detect objects at the fraction of the seismic wavelength. They can be easily reconstructed from the ambient noise, so they don’t require to mobilize seismic sources (passive seismic).

Agoranov, 96 Bis Boulevard Raspail, Paris 75006—FRANCE

Follow us