|

Geolinks in

the Mining industry

|

The mining sector will face increasing pressure to supply the minerals required for the new decarbonized economy. New solutions are required to ensure sustainable mining activities.

|

Main Issue

that we solve

|

Geolinks develops a turnkey innovative monitoring solution with more efficient alarm systems, to give more time to the mining operators to react and prevent accidents.

Despite a lot of safety measures and surface monitoring systems already in place, accidents still occur.

Existing surface monitoring systems can only detect accident precursors when the accident is about to occur and sometimes, it is too late.

Facts:

More than 30,000 Tailings Storage Facilities (TSFs) worldwide, 16,000 currently active (1)

Between 2 and 3 major TSF’s failures every year.

Tailings dam failures and Open pit landslides are among the most catastrophic causes of accident in mining activities, with terrible societal and environmental impacts .

|

What is Geolinks

FlowTerra™ Solution?

|

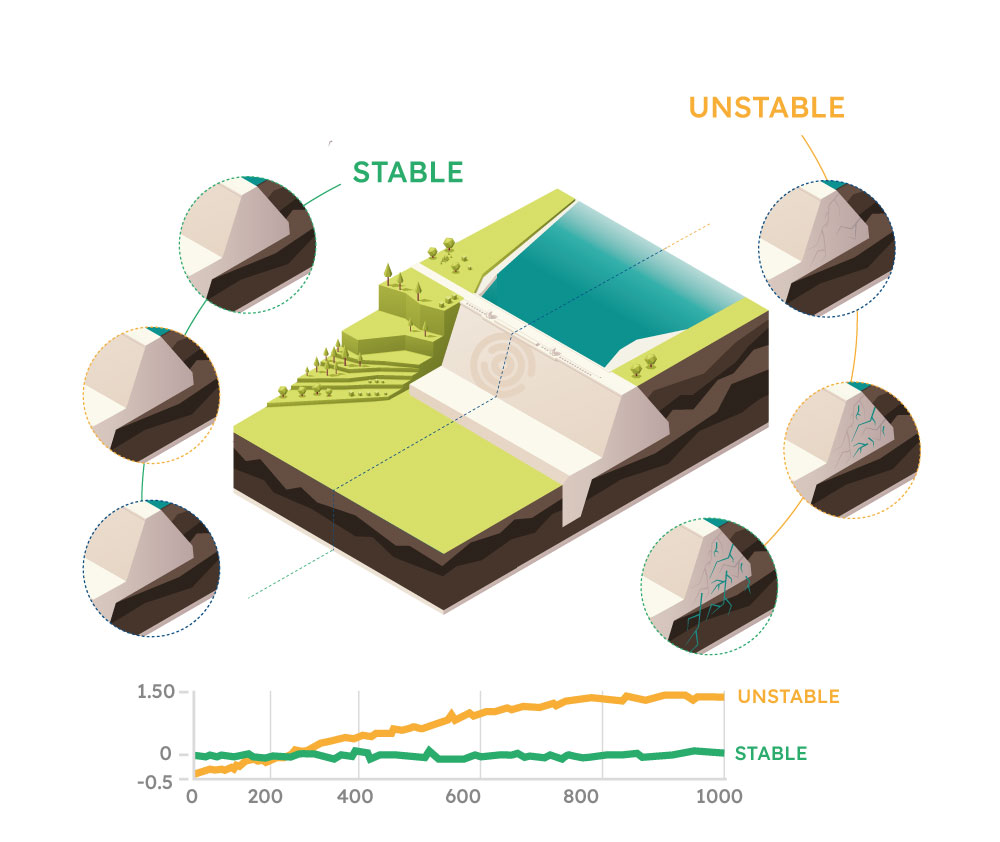

Passive seismic monitoring techniques can detect anomalies before the surface strain sensors because they use acoustic waves propagating deeper and further in the tailings dams or wall structures.

Through strategic partnerships, we propose our solution with High-end Spectral Ground Penetrating (SGPR) inspections, as well as microtremor monitoring.

|

Why choose

FlowTerra™ for Mining?

|

SUSTAINABILITY

Respects people, planet and profit by mitigating risks of dam failures and slope instability.

Increase the security of workers on site and of nearby living communities.

Provides information and key data to develop sustainable and efficient mining activities.

EARLY DETECTION OF ACCIDENT PRECURSORS

Because Passive Seismic uses acoustic waves propagating deeper and further in the TSFs or wall structures, it detects anomalies before the surface sensors or visual inspections.

COST EFFECTIVE & ENVIRONMENTALLY FRIENDLY

No need for seismic sources, no need for dense seismic arrays – Start monitoring with less than 20 sensors. High flexibility in installation to cope with the mining activities.

ENRICHED MONITORING DATA

Agoranov, 96 Bis Boulevard Raspail, Paris 75006—FRANCE

Follow us